Color fastness of upholstery fabrics I

Light fastness

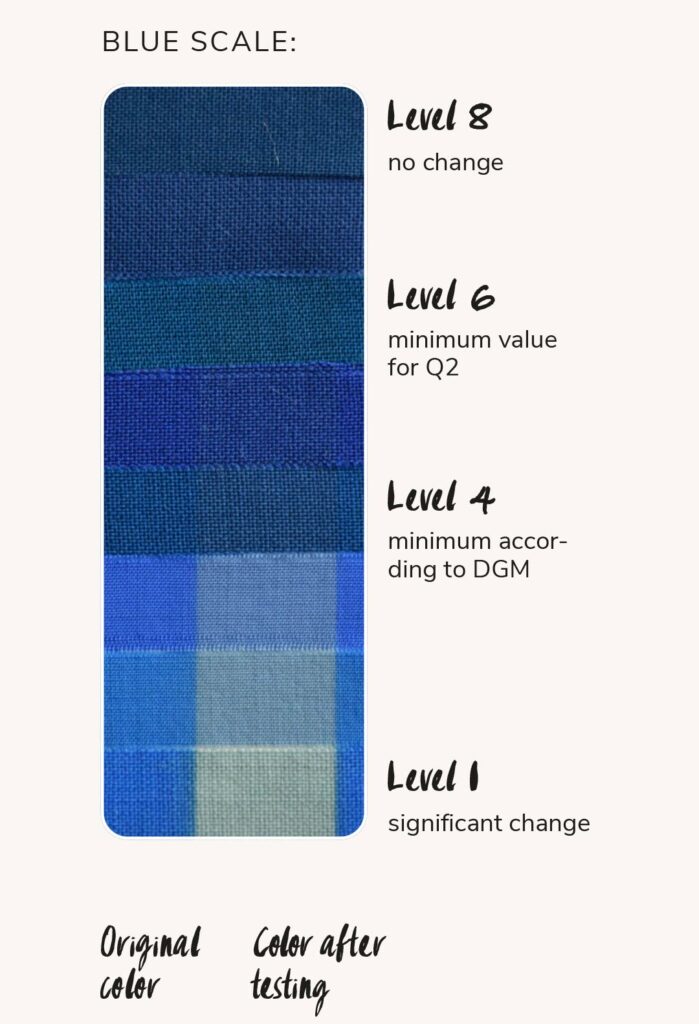

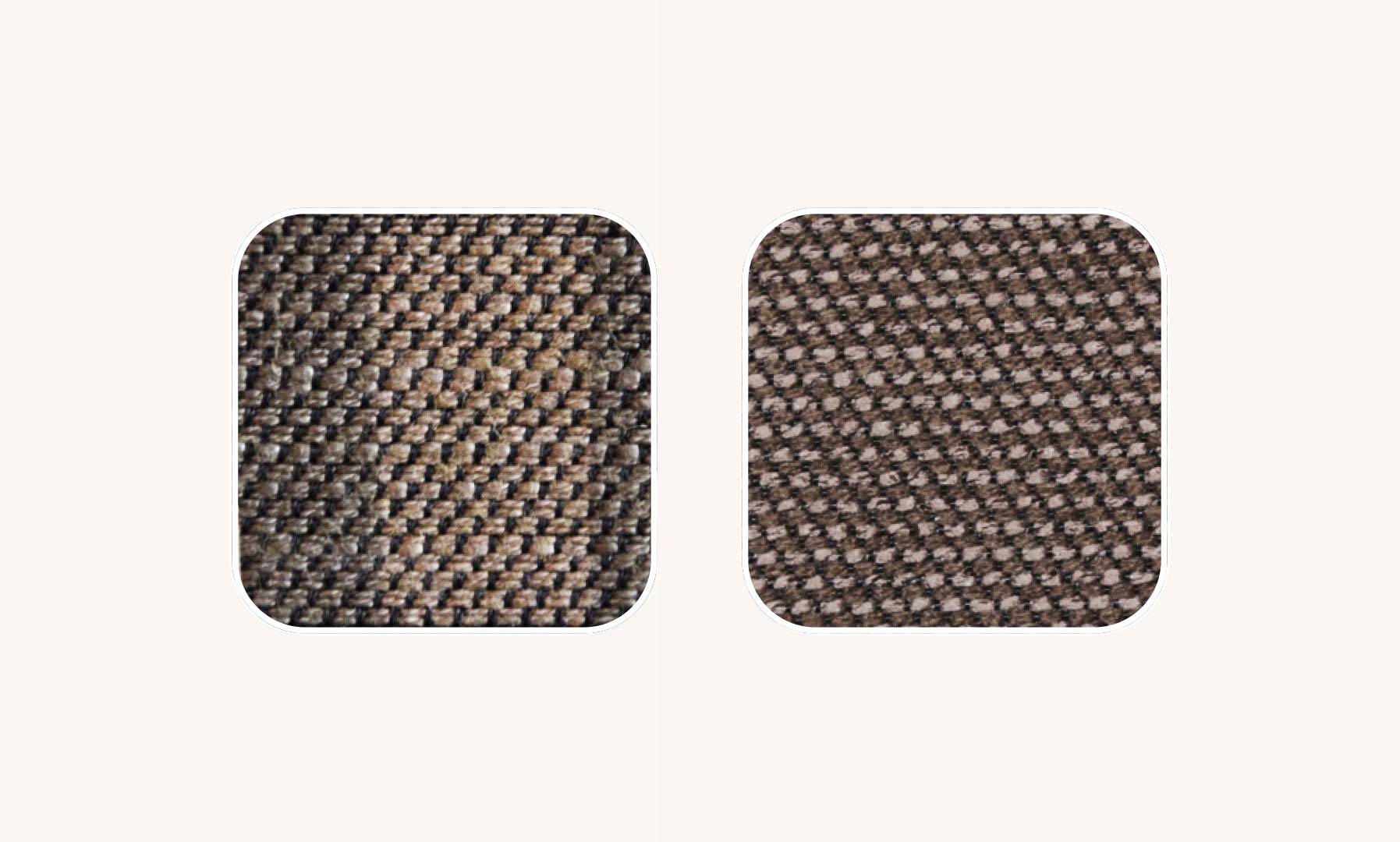

Besides the abrasion resistance (topic in edition no. 4), the color fastness of an upholstery fabric also is a substantial quality criterion. Here a distinction is made between color fastness and light fastness. Abrasion resistance means the resistance of an upholstery fabric against abrasion and rubbing off on other materials. In case of light fastness, the resistance of the fabric against the impact of artificial or natural light is evaluated. LIGHT FASTNESS: When conducting this test, the upholstery fabric is exposed to artificial lighting for a longer period of time (approx. 90 – 110 hours), whereby part of the sample is covered. Depending on the quality of the dye, the part of the fabric exposed to light discolors more or less during this time. The color difference to the original color is then evaluated through a so-called blue scale with 8 levels. This test works as follows: The test result at level 1 shows a significant difference to the original color, at level 8 no change can be seen compared to the original fabric after the test. According to the test regulations for upholstery of DGM (“Deutsche Gütegemeinschaft Möbel e.V.”), at least level 4 is required, for particular high demands it is level 5. The values for all Rohleder brand fabrics are at least at level 6. Only the best dyes are used (dyes for the automotive industry) to ensure optimal conditions for everyday use.

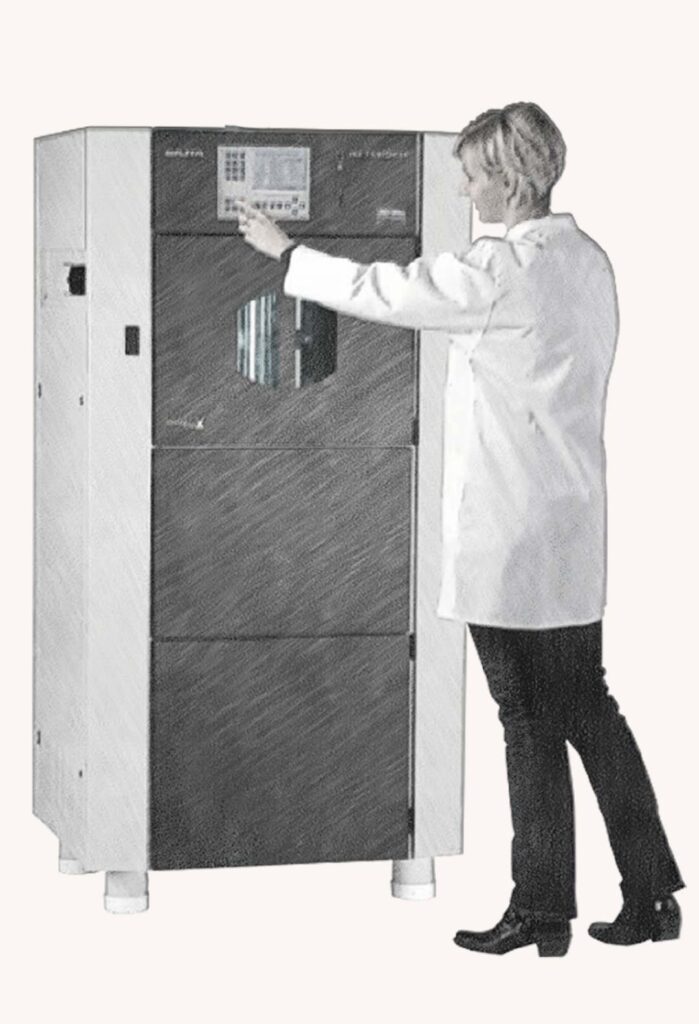

XENON TEST:

The Xenon testing device: In the test room (visible through the viewing window in the middle), the test samples are ex-

posed to the light. To avoid drying, they are continuously moistened during the test. To do so, a water tank is located in the lower part of the device, which is fed by an ultrapure water system. This way straight test results can be guaranteed.