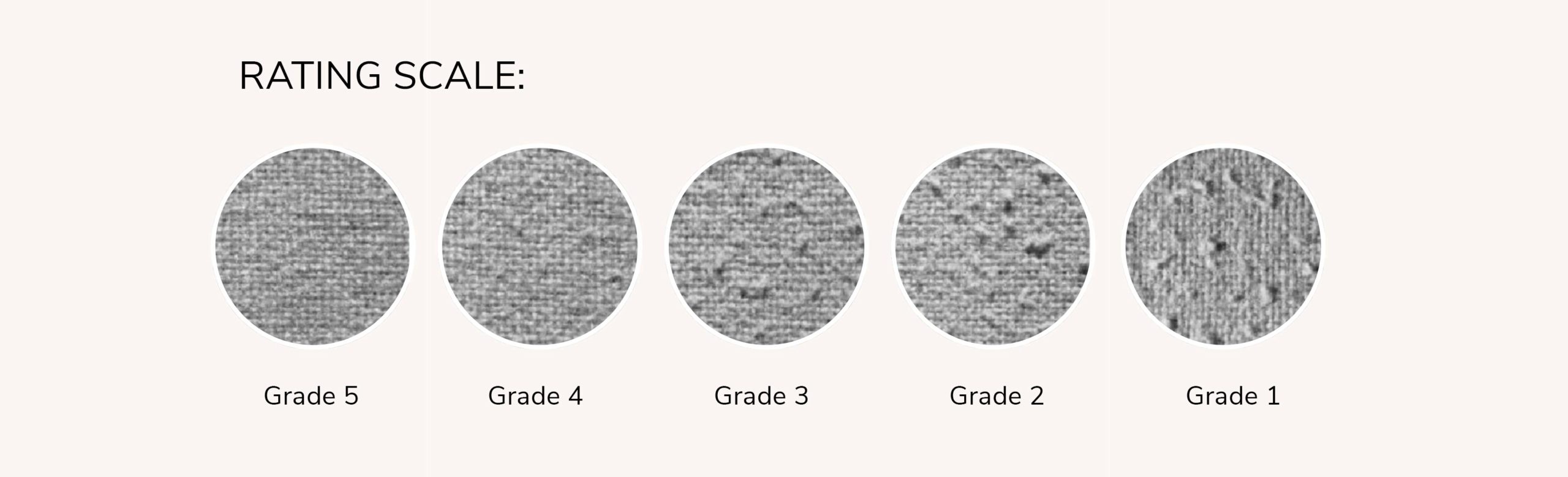

Pilling of upholstery fabrics

EXTERNAL AND INTERNAL PILLING:

A distinction is made between external and internal pilling. With internal pilling the pills form from the fibres of the upholstery fabric itself but with external pilling fibres from other textiles, e.g. blankets, pillows, clothing textiles, etc. adhere to the fibres of the upholstery fabric. These foreign fibres knot together with so-called anchor fibres (individually protruding fibres of the upholstery fabric) to form noticeable pills. The colour of the pills is used to differentiate optically between external and internal pilling. In the case of external pilling the pills usually have a different colour than the cover fabric. External pilling is not a reason for complaint and cannot be regarded as a defect in the upholstery fabric.